Prelam Boards 101: The Shortcut to Quick, Stylish Furniture Finishes

Share

In the fast-paced world of modular interiors, time is just as valuable as design.

Whether you’re setting up an office, designing a rental apartment, or executing large-scale turnkey projects, one material has quietly become the go-to choice for speed, consistency, and cost efficiency — Prelaminated Boards, or simply, Prelam Boards.

They’ve changed how furniture is made — saving time on lamination, reducing waste, and offering ready-to-use finishes that look as good as custom work.

Let’s explore why prelam boards are becoming a favorite among designers and fabricators who want to build fast without compromising on quality.

1. What Are Prelam Boards?

Prelam boards are MDF, particle board, or HDHMR sheets that are already laminated with decorative paper or film on both sides during the manufacturing process.

Unlike traditional boards, which require laminating sheets separately on-site or at a workshop, prelam boards come ready-to-install with the finish baked in — matte, glossy, textured, or woodgrain.

This eliminates an entire step from the furniture-making process, helping modular factories and carpenters save both time and cost.

2. Why Prelam Boards Are a Game-Changer

a. Saves Time and Labor

No need to press, glue, or wait for laminates to bond — just cut, edge-band, and install.

b. Uniform Finish

Factory lamination ensures consistent finish, color, and thickness — perfect for large-scale modular projects.

c. Cost-Effective

Prelam boards are more affordable than buying boards and laminates separately — especially in bulk manufacturing.

d. Easy to Maintain

The factory-fused surface resists scratches and stains better than manual lamination.

3. Where Prelam Boards Are Used

Prelam boards are used in almost every type of furniture:

-

Wardrobes: Interior and exterior surfaces with clean, even tones

-

Kitchens: Overhead cabinets and side panels

-

Offices: Workstations, partitions, and file storage

-

Retail Interiors: Shelves and display units that need quick setup

Designers often mix Prelam MDF for visible areas with plain MDF or plywood for the hidden structure — achieving balance between looks and strength.

👉 Explore Khidki MDF/HDHWR Boards for high-density, smooth-core options ideal for prelam applications and modular assembly.

4. Popular Finishes and Textures

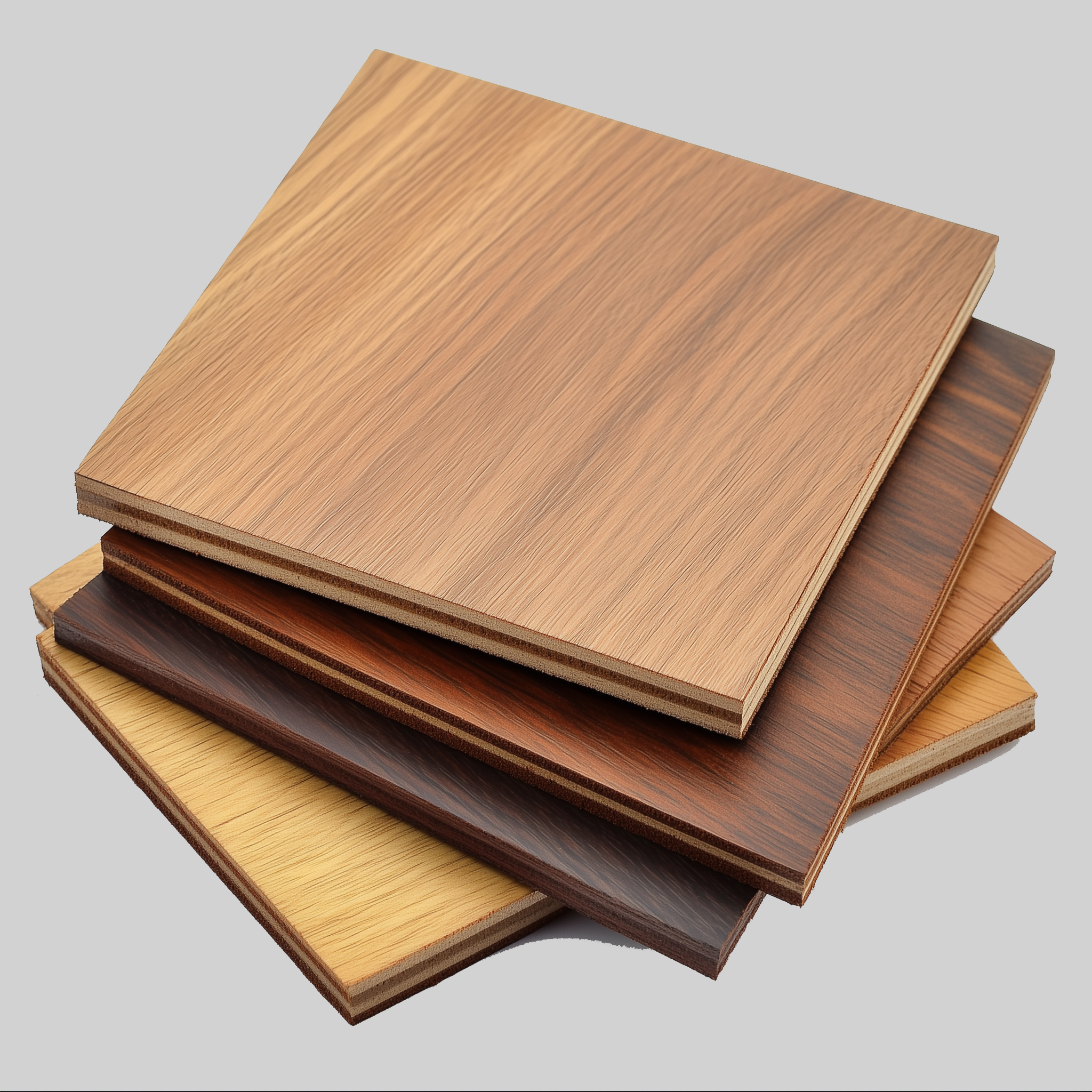

Modern prelam boards go far beyond plain whites and beiges. They’re now available in a variety of finishes, including:

-

Woodgrain textures – walnut, teak, oak

-

Solid matte tones – taupe, charcoal, frosty white

-

Fabric-inspired surfaces – linen, jute, suede

-

High-gloss reflective finishes – for a luxury aesthetic

Some designers also enhance prelam boards by combining them with outer laminates on visible fronts for a more premium finish while maintaining cost efficiency on the sides and interiors.

5. Prelam Boards vs Laminated Boards

| Feature | Prelam Boards | Manually Laminated Boards |

|---|---|---|

| Finish | Factory-finished, consistent | Variable (depends on manual work) |

| Time | Ready-to-use | Requires pressing and curing |

| Durability | Moderate | Higher (depends on adhesive quality) |

| Customization | Limited to available designs | Fully customizable |

So while prelam is unbeatable for speed and uniformity, traditional laminates still win in premium, custom projects. That’s why many designers use both — prelam for bulk work, laminates for detailing.

6. Sustainability and Efficiency

Since prelam boards are made with reconstituted wood fibers and precisely measured coatings, they reduce waste and optimize resource use. The factory-finished process also uses less adhesive and generates fewer emissions compared to on-site lamination.

For modular factories working toward faster, greener production, prelam is both eco-friendly and efficient.

7. When to Choose Prelam Boards

-

You’re working on tight timelines (offices, rental homes, builder fitouts).

-

You need budget-friendly modular furniture with a clean look.

-

You’re manufacturing in bulk or standardized sizes.

Prelam boards are perfect for OEM units, contractors, and builders who value speed, uniformity, and scalability.

The Future of Quick Interiors

As modular living grows, ready-to-use materials like prelam boards will define the next generation of interior projects — fast, flexible, and flawless.

When paired with Khidki Plywood for structure and Kyzen Hardware for smooth motion, you get furniture that installs faster and performs longer.

📞 Call 08045888842 or visit www.khidkihomes.com to explore how engineered materials like MDF, HDHWR, and laminates can simplify your next project.