The Hidden Strength: Understanding the Different Types of Plywood Used in Interiors

Share

Every beautiful piece of furniture has something in common — a strong foundation.

Whether it’s a modern modular kitchen, a full-height wardrobe, or a sleek office workstation, plywood is the invisible hero that holds everything together.

Though often hidden behind laminates and finishes, plywood determines how long furniture lasts, how it performs under stress, and how smooth the final finish feels. But not all plywood is the same — choosing the right one can make the difference between furniture that lasts decades and furniture that fails in months.

In this blog, we’ll explore the different types of plywood, how they’re used in interior projects, and how designers can make smarter material choices for strength, finish, and value.

1. How Plywood Is Made

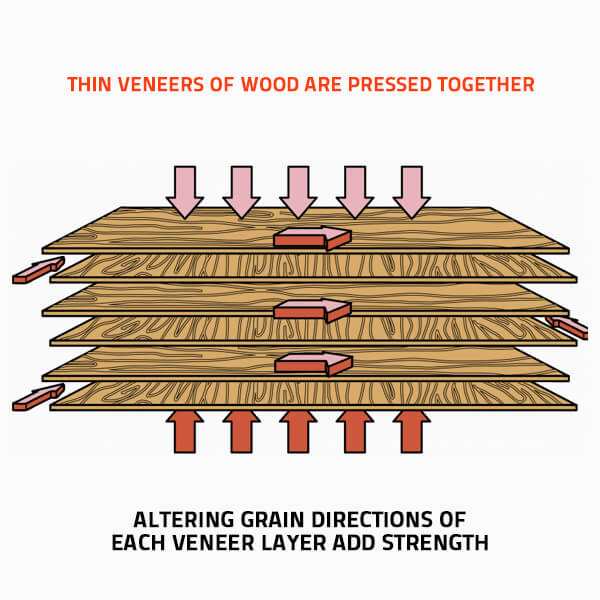

Plywood is crafted by gluing together multiple thin layers (veneers) of wood. Each layer is placed with its grain running perpendicular to the previous one — a process called cross-graining.

This structure gives plywood:

-

Greater dimensional stability

-

Resistance to warping and cracking

-

Strength in multiple directions

At its core, plywood’s performance depends on the type of wood used, quality of bonding, and grade of adhesive.

For example, Khidki Plywood is made from high-density hardwood like eucalyptus and gurjan — known for excellent bonding and uniform density — making it ideal for modular and site-built furniture alike.

2. Common Types of Plywood in Interiors

a. MR Grade Plywood (Moisture Resistant)

Often called commercial plywood, MR grade is perfect for dry areas like wardrobes, beds, wall panels, and office furniture. It resists humidity but isn’t waterproof, so it’s best suited for living and bedroom spaces.

b. BWR/BWP Plywood (Boiling Water Resistant / Proof)

For kitchens and bathrooms, where moisture exposure is high, BWP plywood is the right choice.

Its phenol-formaldehyde adhesive can withstand continuous water contact, making it a favorite among interior contractors for long-lasting performance.

Explore Khidki BWP Plywood for high-strength, calibrated sheets that stay stable in humid conditions — especially in Indian kitchens.

c. Calibrated Plywood

Precision matters — especially for modular furniture factories that rely on CNC routing.

Calibrated plywood is machine-sanded to achieve uniform thickness across every inch, ensuring perfect fit, alignment, and bonding with laminates or veneers.

Khidki’s calibrated range has become a go-to for modular workshops that need consistency for laser cutting, drilling, and edge banding.

3. How to Choose the Right Plywood

Every space has unique functional and environmental needs. Here’s a quick guide:

| Application | Recommended Plywood Type | Reason |

|---|---|---|

| Kitchens, Bathrooms | BWP Grade | Water resistance & high strength |

| Bedrooms, Living Rooms | MR Grade | Cost-effective & stable in dry use |

| Modular Furniture & CNC | Calibrated Plywood | Precise thickness & smooth surface |

| Commercial Projects | BWR or Calibrated | Long-term durability & consistency |

When selecting plywood, also check:

-

ISI Mark (ISI 710 or ISI 303)

-

Core bonding strength

-

Termite & borer resistance

These factors determine how furniture behaves over time — especially in India’s varying humidity conditions.

4. Plywood vs MDF vs Particle Board

Designers often compare plywood to engineered boards like MDF or particle board.

While MDF offers a smooth finish for routed designs, plywood still leads in load-bearing capacity, moisture resistance, and longevity — especially in structural furniture like beds, kitchens, and wardrobes.

For mixed applications, some designers use Khidki MDF/HDHWR Boards for surface panels and Khidki Plywood for the base — achieving the best of both worlds: precision and strength.

5. Sustainability in Plywood

The best plywood doesn’t just perform well — it’s responsibly made.

Modern manufacturing uses plantation wood species, eco-friendly resins, and optimized pressing cycles to minimize waste and emissions.

High-quality plywood like Khidki’s ensures:

-

Reduced formaldehyde emissions

-

Responsible timber sourcing

-

Longer lifespan = fewer replacements

That means more sustainable interiors — both for the environment and for your clients’ budgets.

6. Final Word: The Foundation of Quality Interiors

Plywood may stay hidden beneath laminates and textures, but its importance is undeniable.

Strong furniture begins with strong plywood — and understanding its types helps designers, carpenters, and homeowners make better, longer-lasting choices.

Whether it’s BWP plywood for wet areas, MR plywood for bedrooms, or calibrated sheets for modular accuracy, each type plays a specific role in the strength and beauty of interiors.

📞 Call 08045888842 or visit www.khidkihomes.com to explore plywood that delivers both performance and precision — because every great design deserves a strong foundation.