Introduction

Acrylic sheets, also known as acrylic glass or Plexiglas, are versatile thermoplastic materials widely used in various industries for their clarity, durability, and ease of fabrication. Whether you're considering using acrylic sheets for DIY projects, signage, or architectural applications, understanding their characteristics, benefits, and diverse applications is essential. This guide covers everything you need to know about acrylic sheets.

What are Acrylic Sheets?

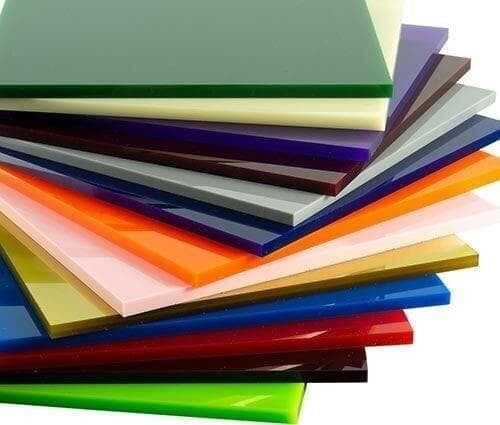

Acrylic sheets are made from polymethyl methacrylate (PMMA), a synthetic resin known for its transparency and impact resistance. They are available in various thicknesses, colors, and textures, offering flexibility in design and application. Acrylic sheets can be transparent, translucent, or opaque, depending on the additives used during manufacturing.

Characteristics of Acrylic Sheets

Clarity: Acrylic sheets offer exceptional optical clarity, allowing light to pass through with minimal distortion. They transmit up to 92% of visible light, making them an excellent alternative to glass for applications requiring transparency.

Durability: Acrylic sheets are highly durable and resistant to impact, weathering, and UV radiation. They do not yellow or become brittle over time, making them suitable for both indoor and outdoor use.

Lightweight: Compared to glass, acrylic sheets are lightweight, making them easier to handle and install. This property also reduces transportation costs and simplifies construction.

Versatility: Acrylic sheets are easy to cut, drill, bend, and shape using common tools. They can be thermoformed into complex shapes without losing their optical clarity or structural integrity.

Weather Resistance: Acrylic sheets have excellent weatherability, maintaining their properties even in harsh environmental conditions. They are resistant to moisture, chemicals, and most solvents.

Applications of Acrylic Sheets

Acrylic sheets find extensive use in various industries and applications:

Architectural and Construction:

- Windows and Doors: Used for glazing applications in residential and commercial buildings due to their clarity and impact resistance.

- Skylights and Roofing: Utilized to provide natural light while offering durability and weather resistance.

- Interior Design: Used for partitions, decorative panels, shelves, and furniture components due to their aesthetic appeal and versatility.

Signage and Displays:

- Signboards: Acrylic sheets are commonly used for indoor and outdoor signage due to their durability, clarity, and ability to be fabricated into various shapes.

- Point-of-Purchase Displays: Used in retail environments to showcase products effectively with illuminated displays or shelving units.

Automotive and Transportation:

- Vehicle Windows and Windshields: Acrylic sheets are used in automotive applications where weight reduction and impact resistance are critical factors.

- Aircraft Windows: Utilized in aviation for cabin windows and windshields due to their lightweight nature and optical clarity.

Industrial Applications:

- Machine Guards: Acrylic sheets are used to provide protective barriers in industrial settings due to their impact resistance and visibility.

- Sound Barriers: Acrylic sheets are employed as noise barriers in industrial and transportation infrastructure to reduce sound transmission.

DIY and Art Projects:

- Picture Frames: Acrylic sheets are used as a lightweight and shatter-resistant alternative to glass in framing artwork and photographs.

- Aquariums and Terrariums: Acrylic sheets are popular for creating custom aquariums and terrariums due to their clarity and ability to be shaped into curved forms.

Considerations when using acrylic sheets

When choosing acrylic sheets for a project, consider the following factors:

Thickness: Select the appropriate thickness based on the application's structural requirements and desired optical clarity.

Color and Finish: Acrylic sheets are available in clear, translucent, and opaque finishes. Choose the color and finish that best suits the aesthetic and functional requirements of your project.

Fabrication Techniques: Acrylic sheets can be cut, drilled, routed, and polished using standard woodworking and plastic fabrication tools. Familiarize yourself with these techniques or consult a professional for complex projects.

Cleaning and Maintenance: Acrylic sheets should be cleaned with mild soap and water using a soft cloth to avoid scratching. Avoid using abrasive cleaners or materials that may damage the surface.

Conclusion

Acrylic sheets offer a combination of optical clarity, durability, and versatility that makes them suitable for a wide range of applications across various industries. Whether you're enhancing the aesthetics of a space, improving safety with protective barriers, or showcasing products with signage and displays, acrylic sheets provide a reliable solution. By understanding their characteristics, applications, and considerations, you can confidently integrate acrylic sheets into your next project, achieving both functionality and visual appeal. Explore the possibilities of acrylic sheets and unleash your creativity in design and