Introduction

In the realm of woodworking and construction, plywood stands as a versatile and indispensable material known for its strength, durability, and versatility. Among the various types of plywood available, fully calibrated plywood represents a pinnacle of precision and quality. In this detailed blog, we explore what fully calibrated plywood entails, its manufacturing process, advantages, applications, and considerations for choosing this specialized material.

Understanding Fully Calibrated Plywood

1. Definition and Characteristics

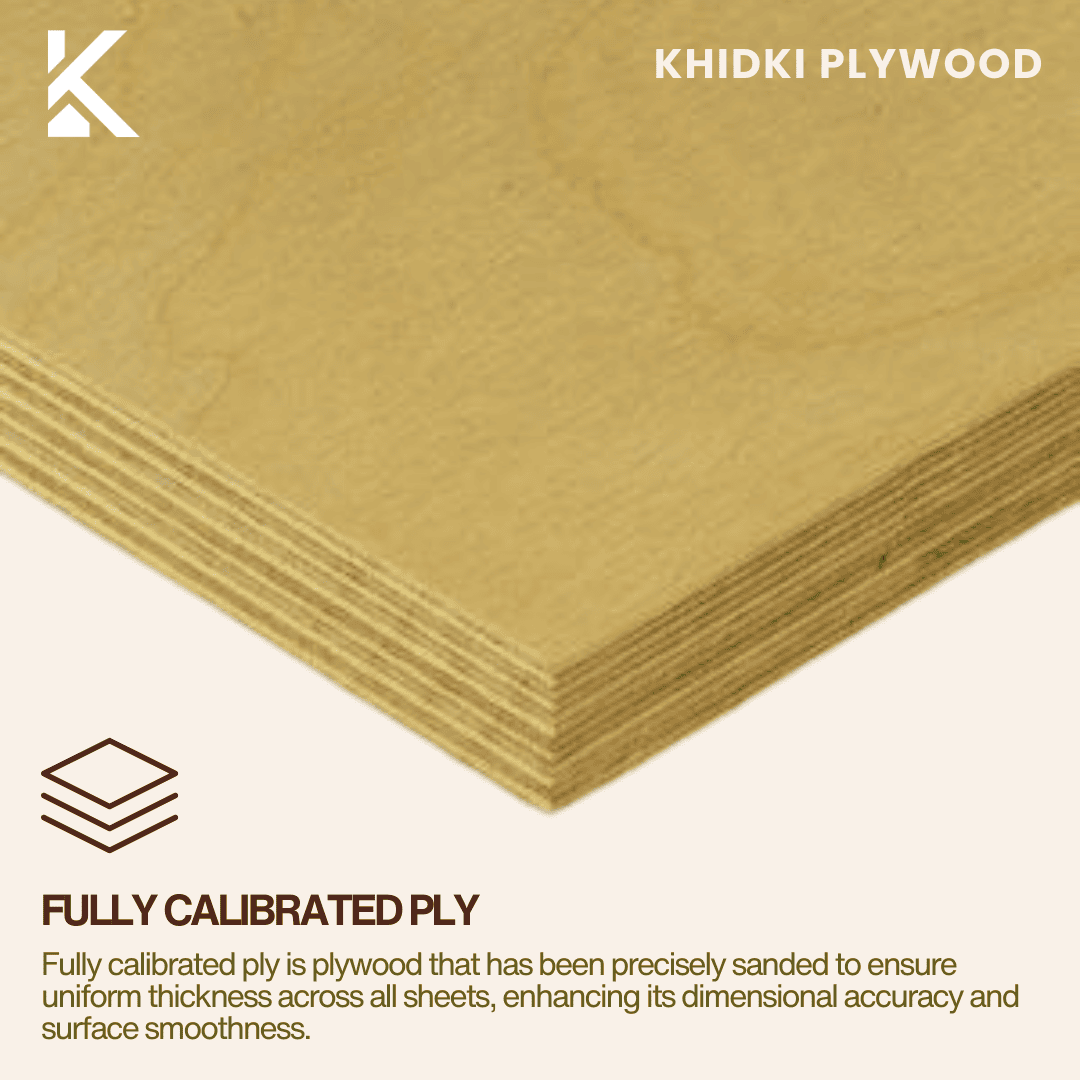

Fully calibrated plywood refers to plywood sheets that are manufactured with precise thickness tolerance across the entire sheet. Unlike standard plywood, which may have slight variations in thickness due to manufacturing processes, fully calibrated plywood undergoes rigorous quality control to ensure uniform thickness. This consistency is achieved through advanced technology and meticulous calibration processes during manufacturing.

2. Manufacturing Process

The production of fully calibrated plywood involves several key steps to achieve uniform thickness and high-quality standards:

Veneer Selection: High-quality veneers, typically sourced from hardwoods like birch, are selected based on their grain structure and strength.

Bonding Process: The veneers are bonded together using high-strength adhesives under controlled pressure and temperature conditions. This ensures optimal bonding strength and durability.

Calibration: After bonding, the plywood sheets undergo precision calibration processes where they are sanded and trimmed to achieve exact thickness tolerances. Advanced machinery and technology are used to ensure uniformity across the entire surface of each sheet.

3. Advantages of Fully Calibrated Plywood

a. Precision and Uniformity: The primary advantage of fully calibrated plywood is its precise thickness consistency. This uniformity allows for accurate cutting, shaping, and fitting during woodworking projects, reducing waste and optimizing material usage.

b. Enhanced Quality: Fully calibrated plywood offers superior quality compared to standard plywood due to its consistent thickness. This results in smoother surfaces and edges, making it ideal for applications where aesthetics and precision are paramount.

c. Strength and Durability: Like other types of plywood, fully calibrated plywood retains the inherent strength and durability of wood. The uniform thickness contributes to structural integrity, making it suitable for both load-bearing and decorative purposes.

d. Ease of Handling: Woodworkers and manufacturers benefit from the ease of handling and machining fully calibrated plywood. The predictable thickness allows for seamless integration into various construction and woodworking projects, from cabinetry to furniture making.

4. Applications of Fully Calibrated Plywood

a. Furniture Manufacturing: Fully calibrated plywood is widely used in the production of high-quality furniture, including cabinets, tables, chairs, and shelves. Its consistent thickness ensures precise fitting and assembly, contributing to the overall craftsmanship of the finished pieces.

b. Architectural Millwork: In architectural millwork, fully calibrated plywood is employed for interior paneling, decorative moldings, and customized built-ins. Its uniformity facilitates intricate detailing and seamless integration into architectural designs.

c. Interior Design: Fully calibrated plywood finds applications in interior design for creating bespoke wall paneling, partitions, and acoustic panels. The consistent thickness and smooth surface finish enhance the visual appeal of interior spaces.

d. Construction and Renovation: Builders and contractors use fully calibrated plywood for structural applications such as flooring underlayment, roofing sheathing, and concrete formwork. Its reliability and dimensional stability contribute to the structural integrity of buildings and renovations.

Considerations When Choosing Fully Calibrated Plywood

a. Project Requirements: Assess the specific requirements of your project, including the desired thickness and application. Fully calibrated plywood is available in various thicknesses to suit different structural and aesthetic needs.

b. Quality Standards: Select fully calibrated plywood from reputable manufacturers known for adhering to stringent quality standards and certifications. Ensure compliance with industry specifications for performance, durability, and environmental sustainability.

c. Budget and Cost: Consider the budgetary implications of using fully calibrated plywood compared to standard plywood or alternative materials. While it may have a higher initial cost, the precision and quality benefits can justify the investment over the long term.

Conclusion

Fully calibrated plywood represents a pinnacle of precision and quality in the realm of plywood manufacturing. Its uniform thickness, enhanced quality, and versatility make it a preferred choice for demanding woodworking and construction projects where precision, durability, and aesthetic appeal are paramount. By understanding its manufacturing process, advantages, applications, and considerations, woodworkers, designers, and builders can make informed decisions that elevate the quality and craftsmanship of their projects. Whether you're crafting fine furniture, enhancing architectural interiors, or constructing robust structures, fully calibrated plywood offers a reliable solution that embodies precision and perfection in every sheet.