How is Plywood Made in India - From Start to Finish

Step 1: Selection of the Tree Species

The first stage is to determine which type of tree will be used to create Plywood.

Various kinds of tree wood is used to manufacture plywood. Examples include Gurjan Wood, Eucalyptus, Poplar, Neem Wood, Rubber Wood, Mahogany, Pinewood, Jungle Wood, Oak etc. The actual wood used depends on the availability, cost and application of the plywood.

Step 2: Debarking

After selecting the log, it is debarked and the uneven top layer is removed with a rolling machine. This evens out the surface of the wood. In some situations, the log is subsequently run through a steamer to improve the peel quality.

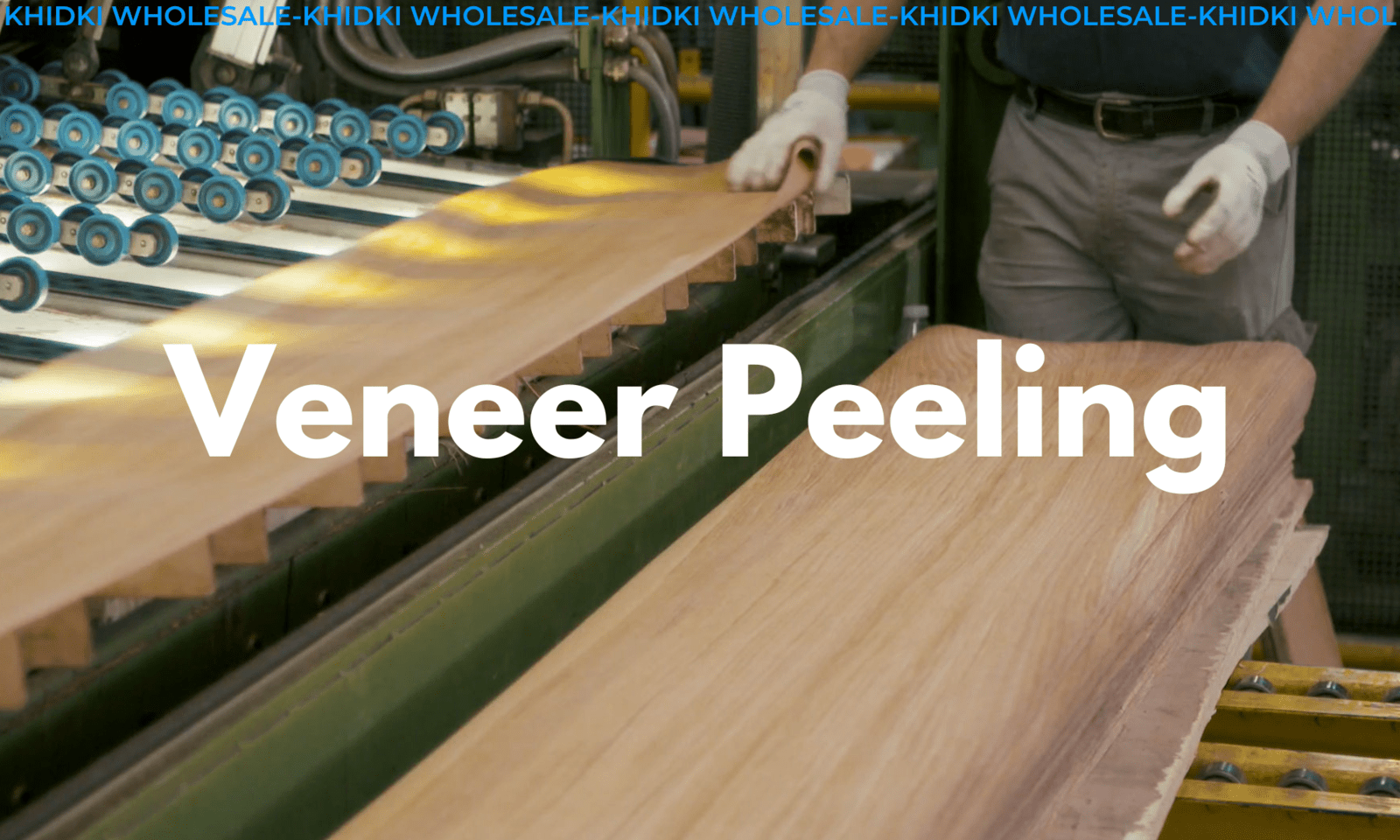

Step 3: Peeling

After the wooden log has been levelled, it is attached to a roller with sharp teeth. The peeling machine converts debarked tree log to veneer sheets of desired dimensions.

Step 4: Veneer Drying

The Cut Veneer are passed through a dryer which exposes the veneers to heat and reduces the moisture content in the veneers. For the plywood to have long life and remain resistant to fungi, it is important that the veneers are dried properly.

Step 5: Gluing/Resin Application

These dried veneer sheets are passed through another rolling machine to apply the resin. The resin type and quality greatly impacts the water resistant property of the plywood.

For Boiling Water Proof (BWP) ply, Phenol Formaldehyde (PF) should be used while for Moisture Resistant (MR) ply, Urea Formaldehyde (UF) resin or Melamine Urea Formaldehyde (MUF) resin is used.

MUF resin provides better water resistance than UF resin (PF resin provides the maximum water resistance).

In this stage, chemicals are also added to prevent the plywood from Borer and Termite.

Step 6: Hot Pressing

The glues veneers are stacked upon each other to create basic plywood formation. The number of layers depends on the thickness of plywood to be made. For example, for 19 mm ply - generally - 11 layers of veneers + 2 face layers are used. The formation is then hot pressed to form the plywood sheet. Proper time should be given for the plywood to cure.

Step 7: Completion

The plywood sheet is then trimmed and finished before being graded.

Step 8: Evaluation

The plywood sheet is next subjected to hammer, nail, and other tests. The qualified sheets are then marked with product and brand details and dispatched to be sold in the market.