Introduction

Plywood is a versatile and essential material used in construction and furniture making. Among the different types, fully calibrated and core composed plywood stands out for its precision, strength, and durability. This blog delves into the manufacturing process, applications, and properties of this superior plywood type.

Calibrated plywood is a high-quality plywood that has undergone a precision process to ensure uniform thickness and a smooth surface. Core Composed Plywood ensures no core- gaps inside the veneer layers of Plywood.

What sets calibrated plywood apart from regular plywood?

How is calibrated and core composed plywood manufactured?

Creating calibrated and core-composed plywood involves a precise and methodical process to ensure quality and consistency. Here's how it's done:

1. Initial Pressing:

- Core Veneers Assembly: Core veneers, without the face veneer, are assembled and placed in a two-way hydraulic hot press. This initial pressing bonds the veneers together under high temperature and pressure.

2. Calibration:

- Thickness Precision: The pressed veneers are then passed through imported calibration equipment. This machinery ensures that the plywood achieves a consistent and uniform thickness across the entire sheet.

3. Final Compression:

- Face Veneer Addition: After calibration, a face veneer is added to the core-composed plywood.

- Final Pressing: The plywood with the face veneer undergoes a final compression to ensure a flawless finish. This step ensures that the plywood surface is smooth and polished.

What is the major application of Calibrated plywood?

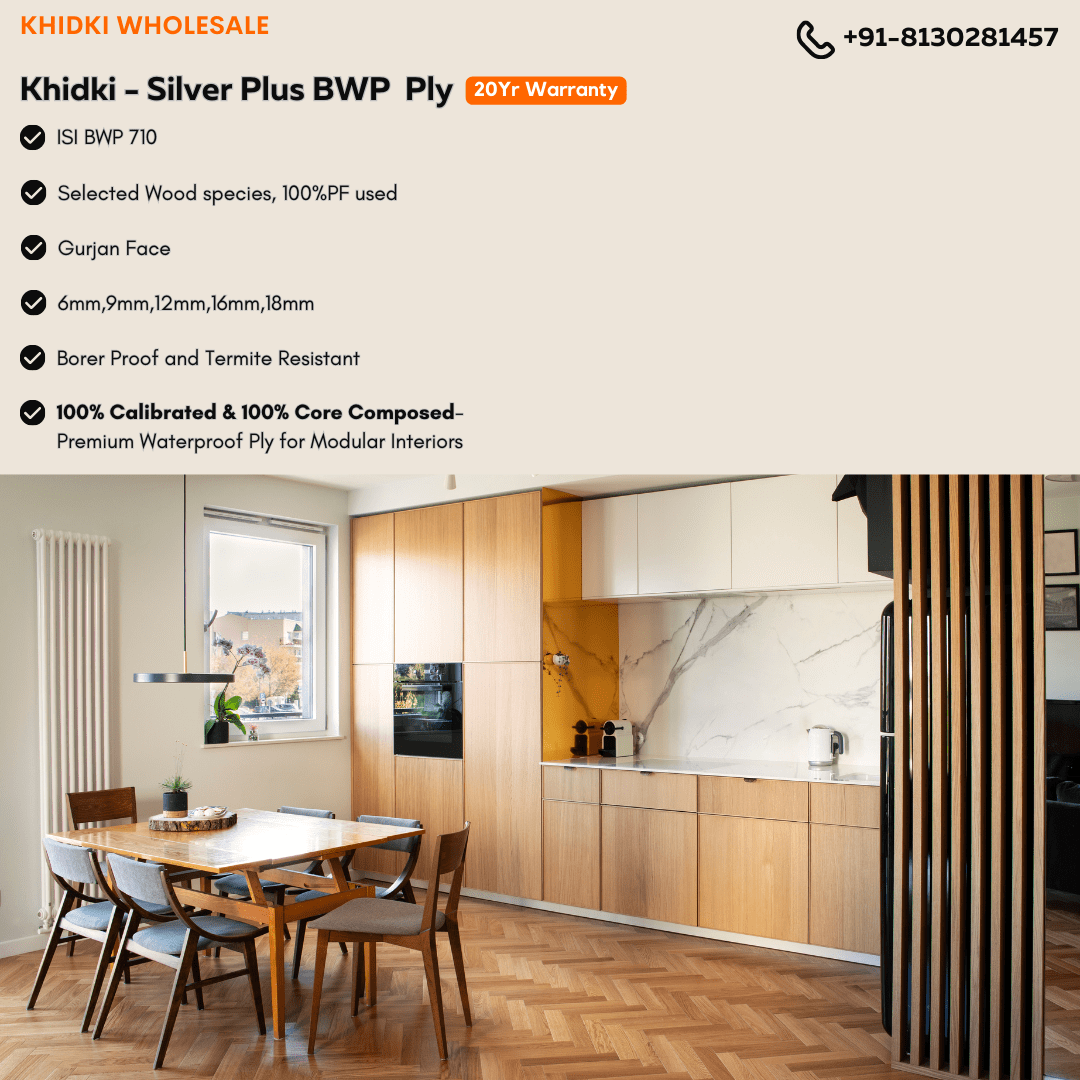

Calibrated Plywood is suitable for creating modular kitchens as well as modular furniture. 19MM thickness Calibrated Plywood are also used in construction of storage units.

Which factors should you focus on while selecting Calibrated Plywood brand?

First and foremost Plywood Grade of Calibrated Plywood - MR Plywood or BWP Marine Plywood . Second, Plywood thickness as per application. Third, Wood Quality used and surface veneer selection. Finally, ISI Certified Plywood with proper checks

Conclusion

Calibrated and core-composed plywood is ideal for high-end furniture, cabinetry, interior paneling, and other applications requiring precision and a smooth finish. This type of plywood is particularly favored in projects where both aesthetic appeal and structural integrity are paramount.

Khidki Homes is Calibrated Plywood distributor in Bangalore. We supply all kinds of Commercial Plywood , Calibrated Plywood and Marine plywood in Bangalore.