A detailed guide to understand Marine Plywood / BWP Plywood

How to Identify Marine Plywood?

How to Identify Marine Plywood?

Marine plywood is a sturdy option perfect for water-based projects like boat construction and docks. Yet, amidst various plywood types, recognizing marine plywood can be tricky. Here, we unveil its key traits to help you spot it accurately.

Features of Marine Plywood to Spot It:

1. Exterior Glue: Look for labels like "Exterior" or "Exterior Grade." This signifies the glue's ability to withstand moisture, ensuring strong ply bonding.

2. Water Resistance: Marine plywood boasts exceptional water resistance, ideal for humid environments. Seek terms like "Waterproof" or "Boiling Water Proof" (BWP) to confirm its water-repelling properties.

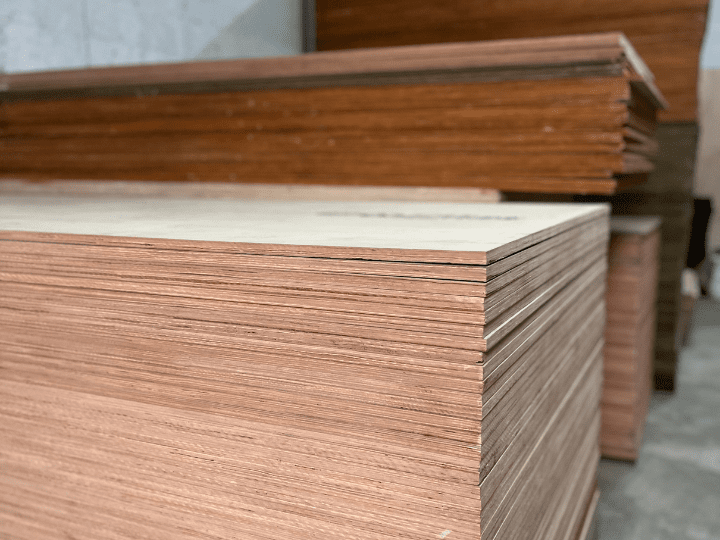

3. High-Quality Veneers: Marine plywood employs top-notch veneers, often hardwoods like mahogany or teak, known for natural water and decay resistance. These sturdy veneers ensure the plywood's longevity and durability.

4. Structural Integrity: With more layers than standard plywood, marine plywood offers superior strength and stability. It typically comprises at least 5 to 7 layers, enhancing its load-bearing capacity and resilience.

5. Certification Standards: Look for certifications like the APA trademark or "Marine Grade" certification to guarantee quality. Organisations such as APA and IMO set industry standards for marine plywood.

By recognizing these features, you can confidently choose marine plywood for your water-based or outdoor ventures, remembering that its quality may vary based on grade.

Can Marine Ply withstand moisture and water?

Marine plywood stands as a best choice in construction and woodworking projects for its robustness. However, questions often arise about its waterproof capabilities. In this blog, we delve into marine plywood's traits and answer the burning query: Is marine plywood waterproof? Let's dive in!

- Understanding Marine Plywood:

Tailored for moisture-laden settings, marine plywood melds top-notch veneers with waterproof glues like phenol-formaldehyde or melamine urea formaldehyde.

- Waterproof Properties Unveiled:

While entirely waterproof, marine plywood flaunts impressive water resistance. The infusion of waterproof glue fortifies its ability to endure moisture and dampness, earning it the moniker "Waterproof Plywood."

- Is Marine Plywood Waterproof?

Absolutely! Thanks to waterproof glue, marine plywood boasts formidable water resistance. This adhesive fosters a sturdy veneer bond, lessening vulnerability to water damage. Nonetheless, prolonged water exposure can affect its performance, subject to grade variations.

Factors Influencing Water Resistance:

Several factors influence marine plywood's water resilience:

- Quality Counts: Opt for marine plywood from reputable sources like KHIDKI BWP PLYWOOD to ensure top-tier water resistance.

- Surface Armour: Shield marine plywood with apt finishes or sealants to bolster its moisture resilience.

- Time Matters: Prolonged water contact can erode marine plywood's water resistance over time. It's better to choose plywood with warranty.

Marine plywood shines for its water resistance, courtesy of waterproof glue. While it can brave occasional water encounters, safeguarding its surfaces and limiting moisture exposure is key. By heeding these insights, marine plywood emerges as a dependable ally in moisture-laden environments.

Why is Marine Plywood different from other Plywood?

Why is Marine Plywood different from other Plywood?

Selecting the right plywood for your construction or renovation ventures demands an understanding of the disparities between different types. Ever stumbled upon Marine Plywood in your research? Let’s unravel its mysteries!

Comparing Marine Plywood vs. Ordinary Plywood:

- Features: Marine Plywood boasts waterproof adhesive and top-tier veneers, whereas ordinary plywood comprises multiple layers of wood veneers.

- Water Resistance: Marine Plywood triumphs in moisture resilience, earning it the moniker "Waterproof Plywood," unlike its counterpart susceptible to warping.

- Exterior Applications: Tailored for outdoor endeavour's like boat building, Marine Plywood reigns supreme, while ordinary plywood finds its niche indoors.

- Quality and Durability: Marine Plywood boasts high-quality, enduring traits, though variance may occur across grades, unlike ordinary plywood, which varies in quality.

- Cost: Expect Marine Plywood to be pricier, while ordinary plywood leans towards affordability.

- Plywood Grading System: Marine Plywood adheres to higher standards, denoted by labels like "Marine grade," whereas ordinary plywood follows a standard grading system.

- Strength: Marine Plywood flaunts superior strength and resistance, a feature not universally shared by ordinary plywood.

- Formaldehyde Emission: Certain Marine Plywood types emit minimal formaldehyde, unlike some variants of ordinary plywood.

- Longevity: Marine Plywood braves harsh elements, ensuring durability, whereas ordinary plywood may falter over time in adverse conditions.

Marine Plywood shines in water resilience and endurance, ideal for outdoor ventures. Conversely, ordinary plywood, budget-friendly and versatile, suits indoor and non-structural projects. To ace your project, weigh each type's pros and cons and seek expert advice. Remember, a well-informed choice spells success! Connect with us at Khidki for guidance on your plywood pursuits.

What are the advantages of Marine Plywood?

What are the advantages of Marine Plywood?

1. Strength and Durability: Crafted from top-tier veneers and robust adhesives, marine plywood doesn't shy away from heavy-duty tasks. It's a reliable choice for boat hulls and other structural components requiring robust materials.

2. Water Resistance: Marine plywood thrives in wet conditions, thanks to its adeptness at repelling moisture and humidity. It's the go-to choice for projects where water is a constant companion, like boat decks and docks.

3. Dimensional Stability: Marine plywood maintains its shape and structure even in fluctuating environments, minimising the risk of warping or twisting.

4. Decay and Pest Resistance: Treated with preservatives, marine plywood wards off decay and fungal growth, making it less appealing to wood-damaging pests.

5. Longevity and Cost-effectiveness: With its extended lifespan and minimal maintenance requirements, marine plywood proves to be a cost-effective investment in the long run.

6. Versatility: Marine plywood is a flexible ally, easily adaptable to various design requirements and project needs. Its smooth surface allows for effortless customization and aesthetic enhancements.

Where is Marine Plywood Used?

From boat building to outdoor furniture and marine construction, marine plywood finds its footing in an array of applications, ensuring durability and reliability where it matters most.

Marine plywood emerges as a stalwart companion in marine and outdoor construction, offering a winning combination of water resistance, strength, and longevity. Its myriad benefits cater to a diverse range of projects, ensuring enduring performance and structural integrity. Ready to embark on your marine plywood journey? Dive into the world of Khidki Plywood Range for top-quality marine plywood solutions tailored to your needs.

For any queries or assistance, reach out to our experts at Khidki. We're here to guide you every step of the way!